PRODUCT

PROMINENT INITIATOR OF MASK SOLUTIONS

Products introduction

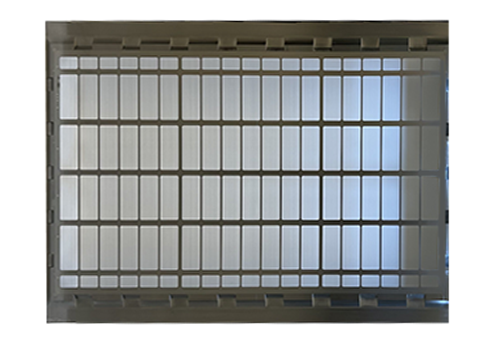

Mask Frame

The Mask Frame is a foundational structure used for welding the Mask Sheet. It securely holds the Mask Sheet in the correct position, ensuring that organic materials are deposited accurately and that the Mask remains stationary, forming a uniform layer.

The frame also protects the Mask from deformation due to heat and pressure. PIMS's Mask Frame is characterized by high precision in alignment hole processing, ensuring that the Mask can be fixed in the exact position. Additionally, it features excellent flatness, minimizing deformation even after the Mask is attached.

OLED Metal Mask

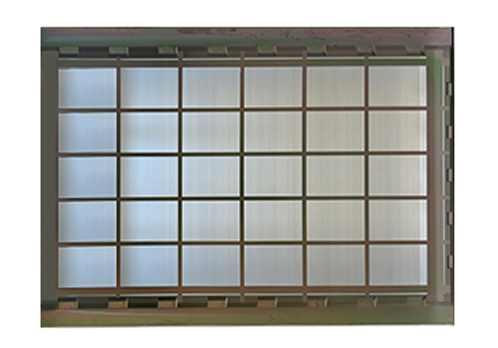

OMM(Open Metal Mask)

The OMM (Open Metal Mask) is an essential process product used in the manufacturing of OLED displays. It selectively evaporates organic materials for the common layer across the entire emission area of the panel.

S-MASK

The S-Mask is an advanced product based on the conventional OMM, with PIMS's patented technology applied. It utilizes an enhanced etching process to reduce half-etching depth, forming a tapered cross-section, and significantly minimizing shadow areas during the evaporation of organic materials.

This makes it advantageous for designing narrow bezel products. The half-etching depth in the open areas that causes shadow area can be precisely controlled to a fine level of around 10 µm.

F-Mask

The F-Mask is a product that integrates the Cover/Support Stick used to support the FMM (Fine Metal Mask), with PIMS's patented technology applied. In addition to the traditional rectangular shape, it is easy to manufacture in various shapes such as notches and irregular forms, making it suitable for supporting diverse designs like those used in auto and watch display.

The F-Mask offers higher precision compared to separately produced Cover/Support Stick and contributes to reducing FMM welding time for customers.

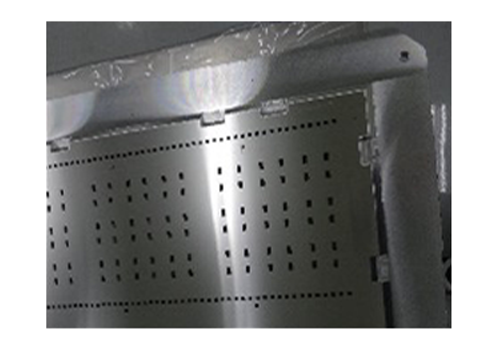

CVD Mask

The sub-pixels that create colors are made of organic materials, which deteriorate in lifespan when exposed to moisture and oxygen. To prevent this, a sealing process is employed, known as the Encapsulan (bagging process), in which the CVD Mask is used.

The CVD Mask, completed with PIMS's proprietary coating technology, minimizes distortion of the Mask's precision during high-temperature coating processes.

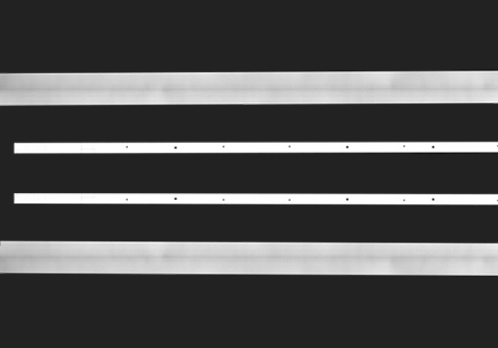

Stick

Stick is used in various applications related to large mask for deposition in large display, including Mask Stick, Align Stick, and Cover/Support Stick.

PIMS possesses advanced technology that ensures total pitch precision, high-quality etching, and effective taper formation. This allows for the creation of stick in custom shapes as desired by the customer, with thicknesses ranging from a minimum of 0.03 mm to 0.3 mm and lengths up to over 3,000 mm.

Cleaning

The cleaning process for Metal Mask involves removing organic and inorganic substances (particles) from the product surface using ultrasonic technology. The residual moisture is then dried using a baking process, which helps reduce corrosion rates and enhance the product's durability.

Coating

The coating process for Metal Mask involves creating an insulating layer on one or both sides of the product using a sputtering method in a vacuum chamber. The film thickness can range from 1.0㎛ to over 4.0㎛, with uniformity within 5% and coverage exceeding 90%, ensuring high product quality.